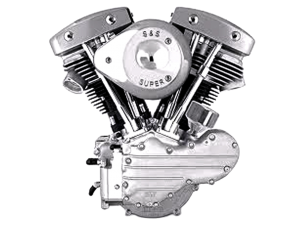

Unmatched Performance & Durability since 1983

JPrecision specializes in high performance machining of engines components. We let your local qualified mechanics to do the final assembly. Contact your local dealer for more details.

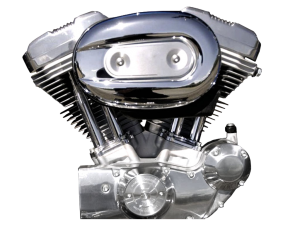

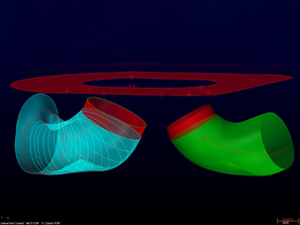

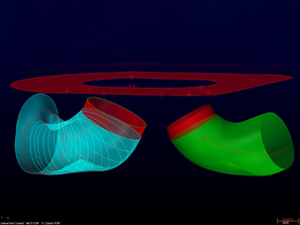

3D Port Design

Using the latest CAD technology, we design and develop high flowing intake and exhaust ports for various Harley-Davidson™ cylinder heads.

5 Axis CNC Cylinder Head Porting

Our 5-axis CNC cylinder head porting center uses computer control to accurately replicate our best porting designs.

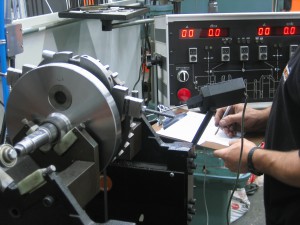

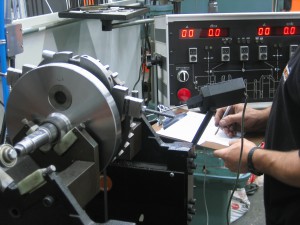

Valve seats machining

JPrecision high flow valve seat profiles are designed in house and are machined on a NEWEN CONTOUR CNC valve seats machine to give you the most accurate and efficient seat job in the industry, resulting in more power and durability.

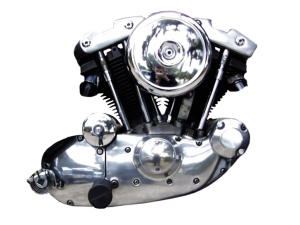

JPRECISION offers a complete cylinder boring & honing services.

Using state of the art equipment, the cylinder is first bored close to it’s final size and it’s then taken to our precision honing machine for final sizing and surface finish. Using precision measuring instruments, we hone the cylinder for a perfect fit to the piston. Proper clearance allows for a better ring seal, longer life, and MORE POWER.

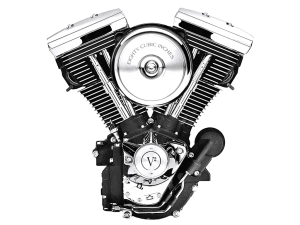

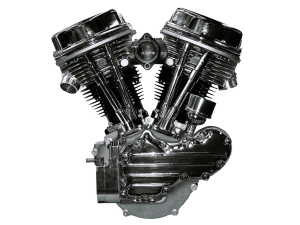

Twin Cam Cranks

Back in 1999, JPrecision was the first shop in the industry to design and build the tooling and fixtures to correctly disassemble, realign and reassemble the Twin Cam flyweels assembly.

We rebuild them stronger than new!

Crank rebuilding

Available for Twin Cam, Evolution, Shovelhead & other models

- Crankpin tig welding

- Dynamic balancing

- « B » to « A » TC crank conversion

- Sprocket shaft straightening

- Super strong 4340 connecting rods in stock

From engine case boring to Timken bearing conversion,

J PRECISION offers you a one stop destination.

Unmatched Performance & Durability since 1983

JPrecision specializes in high performance machining of engines components. We let your local qualified mechanics to do the final assembly. Contact your local dealer for more details.

3D Port Design

Using the latest CAD technology, we design and develop high flowing intake and exhaust ports for various Harley-Davidson™ cylinder heads.

5 Axis CNC Cylinder Head Porting

Our 5-axis CNC cylinder head porting center uses computer control to accurately replicate our best porting designs.

Valve seats machining

JPrecision high flow valve seat profiles are designed in house and are machined on a NEWEN CONTOUR CNC valve seats machine to give you the most accurate and efficient seat job in the industry, resulting in more power and durability.

JPRECISION offers a complete cylinder boring & honing services.

Using state of the art equipment, the cylinder is first bored close to it’s final size and it’s then taken to our precision honing machine for final sizing and surface finish. Using precision measuring instruments, we hone the cylinder for a perfect fit to the piston. Proper clearance allows for a better ring seal, longer life, and MORE POWER.

Twin Cam Cranks

Back in 1999, JPrecision was the first shop in the industry to design and build the tooling and fixtures to correctly disassemble, realign and reassemble the Twin Cam flyweels assembly.

We rebuild them stronger than new!

Crank rebuilding

Available for Twin Cam, Evolution, Shovelhead & other models

- Crankpin tig welding

- Dynamic balancing

- « B » to « A » TC crank conversion

- Sprocket shaft straightening

- Super strong 4340 connecting rods in stock

From engine case boring to Timken bearing conversion,

J PRECISION offers you a one stop destination.

Porting and Optimisation

The more you learn about High Performance engines, the more you will enjoy your motor heads modified JPrecision.

The result is maximum power, acceleration and durability that you can get yourself.